Enhance the strength and abrasion resistance of wool products using filament spun yarn technology for circular, flat-bed and warp knitted products.

Harness the wool fibre’s breathability, elasticity, softness and strength with filament spun yarn technology. From filament core spinning to filament wrap spinning, explore the two most common methods of enhancing wool to extend the lifetime and benefits of the wool fibre for durable products.

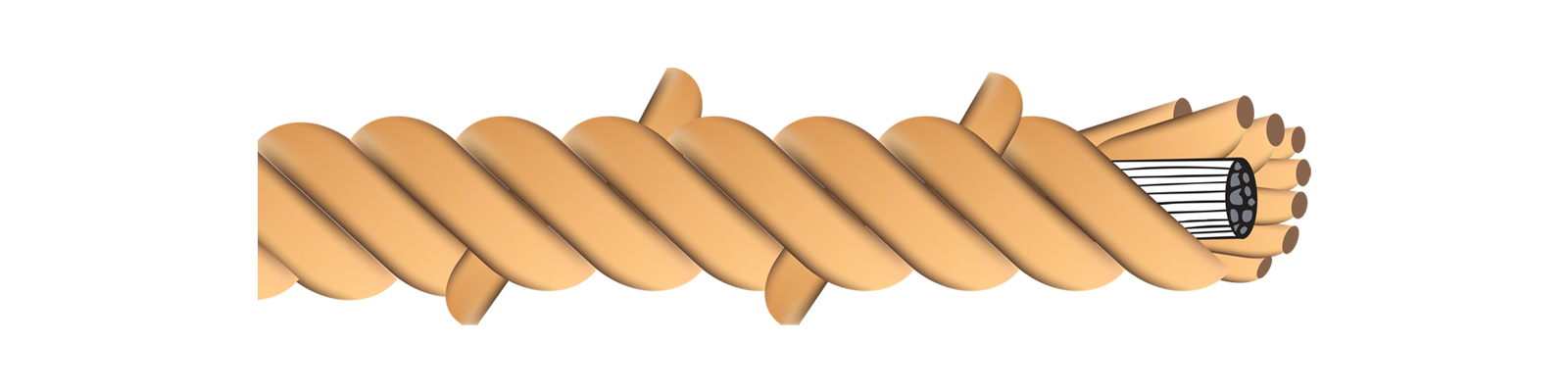

Filament Core Spinning

How It Works

In filament core spinning, a filament – a long, thin strand or thread – serves as the central yarn around which other fibres are wrapped to create a strong or flexible core for yarn.

Filament core spinning involves wrapping wool or wool-blended fibres around a central filament yarn like elastane or multiple filaments such as polyester, polyamide or regenerated cellulose.

The wrapping process of filament core spun yarn can involve either a single strand of wool roving or double roving wrapping, with the latter helping to give a better coverage of the core yarn. This yarn helps to enhance the strength of the yarn, while maintaining the hand feel and appearance of the wool yarn as a robust outer shell.

If additional elasticity is required, elastane or stretchy filament yarn such as PBT (polybutylene terephthalate) can be use as the core. Depending on the choice of the filament core, extra functional properties can be added such as far infrared function, ceramic cooling, quick drying capabilities and more.

Filament Core Spinning

Product Applications

- Lightweight circular knits for sports/outdoor base layers

- Circular seamless knitted products

- Flat-bed knitwear, particularly for complete garment knitting without seams

- Weavable singles yarn used as warp and weft for lightweight woven fabric

- Stretch wool products using an elastane core

- Flat-bed knitted products for footwear

No matter the product application, the benefits of filament core spinning provide enhanced yarn strength that is stronger than conventional spun yarns of the same weight, with increased elasticity by an elastane core. Filament core spinning with wool offers the soft handle and appearance of wool, with the inherent properties of the wool fibre, with machine washability available depending on the specific type of wool chosen.

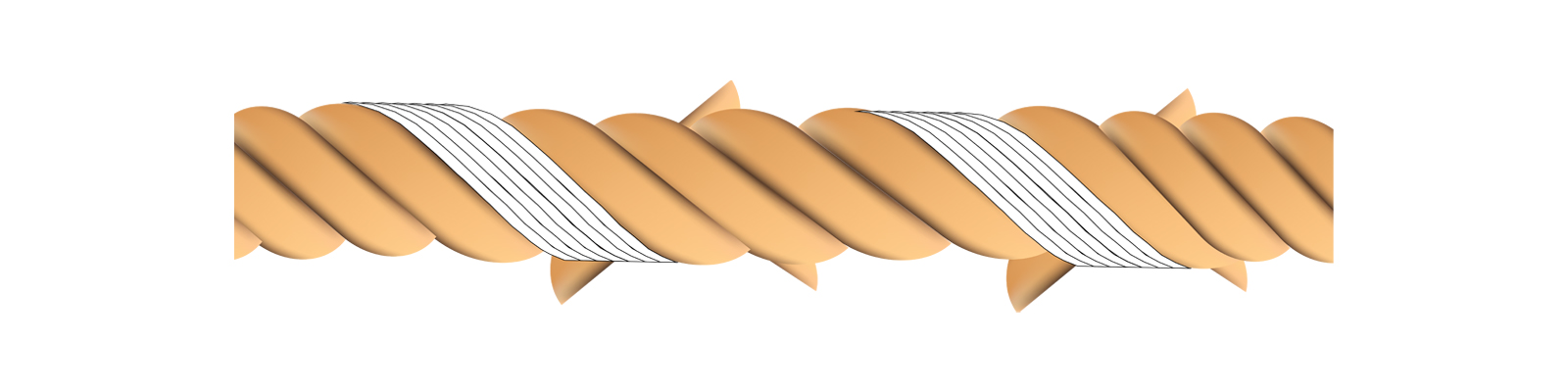

Filament Wrap Spinning

How It Works

In filament wrap spinning, a fine synthetic filament yarn such as polyamide or polyester, is wrapped around a core made from wool or wool blend roving. This wrapping process partially covers the wool yarn with a synthetic filament yarn.

In traditional wrap-spun yarns, a single strand of filament yarn wraps around the core wool or wool blend fibre, such as occurs in Sirofil spinning. However, with advancements in spinning technology, double filament wrapping technology is now available, creating a yarn with less spirality, enhanced drape, improved comfort and ease of handling.

Filament wrap spinning with wool gives extra strength to the yarn to be made into durable and resilient fabric. By incorporating a small proportion of synthetic filament, the strength of the resulting yarn is given a significant boost while maintaining the characteristics of wool in ultra-lightweight applications.

Filament Wrap Spinning

Product Applications

- Significant strength enhancement

- Improved abrasion resistance

- Enhanced pilling performance

- Smooth surface of the fabric with less hairiness

- Machine washable if relevant wool fibre is used

- Coarser wool fibre can be adopted to achieve a comparatively finer yarn count

Today, there are other types of spinning systems for filament yarns with staple fibres to form composite yarns. For example, Manerd™ composite yarn which use static electricity and spinning with the filament-opening technology to intertwine the filament with wool fibre.